Mastering ISO 9001 Quality Objectives: A Guide to Operational Excellence

ISO 9001 Quality Objectives are the bedrock of an organization’s Quality Management System (QMS), serving as measurable targets that drive the enhancement of product and service quality. These objectives are not mere aspirations but quantifiable and actionable goals that reflect an organization’s commitment to customer satisfaction and continuous improvement.

Another aspect of quality objectives is the ability for the organization to put the ISO 9001 standard to practice. This is where the ISO standard offers value to the organization, rather than being a hindrance.

The Significance of ISO 9001 Quality Objectives

Quality objectives are essential because they:

Check Out Our Great Selection of ISO 9001 Online Training Courses

Looking to master ISO 9001:2015 or ensure top-notch training for your team? Explore our Online Courses here!

- Translate the Quality Policy into operational plans for continuous improvement: Quality objectives serve as a conduit, transforming the high-level intentions of the Quality Policy into specific, actionable plans. This translation is crucial because it ensures that the abstract principles of the policy are brought to life through practical, on-the-ground actions that propel the organization towards its goals.

- Highlight and focus on key elements of the Quality Policy: By setting quality objectives, an organization can pinpoint the most critical aspects of its Quality Policy. This focus helps to channel resources and attention to the areas that will have the most significant impact on quality, ensuring that efforts are not diluted across too many initiatives.

- Direct efforts towards specific, measurable performance improvements: Quality objectives provide a clear direction for what needs to be achieved and by when. They act as signposts that guide the organization’s journey towards quality excellence, ensuring that every team member understands the targets and works collaboratively to achieve them.

- Establish benchmarks for monitoring and evaluating effectiveness: Without measurable objectives, it would be challenging to gauge the success of quality initiatives. Quality objectives set the standard against which actual performance is measured, allowing for an objective evaluation of whether the strategies implemented are delivering the desired outcomes.

Expanding on the importance of quality objectives, these benchmarks are not static; they are dynamic tools that should evolve as the organization grows and as customer and market demands change. They are the yardsticks by which continuous improvement is measured, providing a feedback loop that informs the management about the effectiveness of their QMS. This feedback is critical for making informed decisions that can lead to process enhancements, waste reduction, and better resource allocation.

Expanding on the importance of quality objectives, these benchmarks are not static; they are dynamic tools that should evolve as the organization grows and as customer and market demands change. They are the yardsticks by which continuous improvement is measured, providing a feedback loop that informs the management about the effectiveness of their QMS. This feedback is critical for making informed decisions that can lead to process enhancements, waste reduction, and better resource allocation.

Moreover, quality objectives act as a motivational force for employees. When staff can see the tangible goals their work is contributing towards, and when they witness the progress being made, it can significantly boost morale and engagement. This increased engagement not only leads to a more satisfied workforce but also to higher quality products and services, as employees take ownership of the outcomes and strive to meet or exceed the set objectives.

In essence, quality objectives are the driving force behind an organization’s quality improvements. They provide clarity, direction, and a sense of purpose, all of which are essential for fostering an environment of excellence and for achieving the ultimate goal of customer satisfaction.

Crafting SMART Quality Objectives

To ensure that quality objectives are effective, they must be SMART:

Specific

- Objectives should be clear and concise, such as reducing the defect rate in a product from 10% to 5% within six months.

Measurable

- Progress and success must be quantifiable, allowing the organization to track and determine the achievement of objectives.

Attainable

- Objectives should be realistic and achievable with available resources and capabilities.

Relevant

- They must align with the organization’s strategic goals and meet customer or statutory requirements.

Time-Oriented

- A definitive timeline for completion is crucial for planning, monitoring, and evaluating progress.

Implementing Quality Objectives

A detailed action plan is essential for achieving quality objectives, including:

- Actions to be taken: Outline the steps required to meet the objectives.

- Resources required: Identify what is needed in terms of materials, personnel, and budget.

- Responsible individuals: Assign accountability for each action.

- Deadlines: Set clear time frames for each objective.

- Evaluation methods: Determine how results will be assessed.

Documentation and Evaluation Methodology

ISO 9001:2015 emphasizes the importance of documenting quality objectives for validation and decision-making. Establishing a robust evaluation mechanism, such as management reviews or internal audits, is crucial for assessing the effectiveness of the objectives and ensuring they remain aligned with the strategic direction. Not only that, but you want to ensure that your quality objectives are in alignment with your ISO 9001 Quality Policy. But how does one do that?

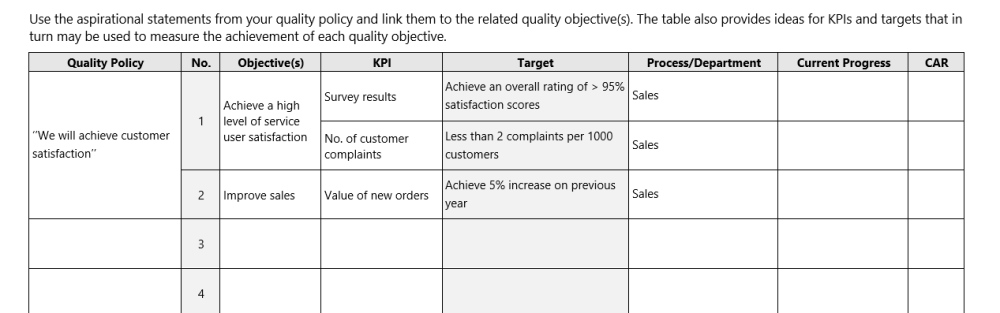

One way is to create a Quality Objectives and KPI Register with aspirational statements of your Quality policy next to a particular objective. Check out the image below to see an example of this:

Notice in the above image that the aspirational statement of the quality policy is in alignment with two quality objectives. Also note that the objectives are associated with Key Performance Indicators (KPI’s) and that each KPI is associated with a target that can be measured. This is key to helping an organization improve upon their management system.

Notice in the above image that the aspirational statement of the quality policy is in alignment with two quality objectives. Also note that the objectives are associated with Key Performance Indicators (KPI’s) and that each KPI is associated with a target that can be measured. This is key to helping an organization improve upon their management system.

Also note that there is a current progress column. This can be used to document the current progress of the particular objective at any given time. This can be used to discuss the quality objectives during a Management Review Meeting and make any necessary adjustments or discuss how to reach the target(s) if they are not being met.

That brings us to the next column. You will notice the last column is meant for a CAR. Yes, a corrective action. This allows the organization to use the corrective action process to proactively help them meet their quality objectives and KPI’s. So, the question is, should they be escalated to corrective action, or to an opportunity for improvement? I believe the answer lies in the risk associated with the issue.

In other words, the higher risk (determined by upper management) issue, should be escalated to a CAR, whereas a lower risk issue should be escalated to an Opportunity for improvement. I bring this up, because during an ISO 9001 external audit, it is likely an auditor will ask for some type of documented objective evidence that the organization is taking action when a KPI is not met. This is a part of the documentation of quality objectives. I often times see auditors give nonconformities in this area.

Aligning Quality Objectives with Strategic Goals

Quality objectives should not only comply with ISO standards but also support the organization’s strategic direction. This is discussed more in the context of the organization in ISO 9001. This alignment ensures that every objective contributes to the broader vision and mission of the company.

Keep in mind when establishing these quality objectives, that they not only add value, but they are attainable, but not too easily attainable. In other words, you want to make sure you stretch yourselves as an organization so that you are continually improving upon your management system and offering more value to your customers. Isn’t this the main purpose of your quality management system after all?

Translating Strategic Direction into Quality Objectives

To effectively translate strategic goals into quality objectives, organizations should:

- Understand their strategic direction thoroughly.

- Use the strategic direction as input for developing the Quality Policy and objectives.

- Integrate considerations for risk management, monitoring, measurement, and management review processes.

Monitoring and Revising Quality Objectives

For quality objectives to remain relevant and effective, they require ongoing oversight, which involves:

- Tracking the progress of action plans against objectives.

- Measuring Key Performance Indicators (KPIs) to evaluate success.

- Regularly revising objectives to reflect changes in organizational strategy, customer requirements, or market conditions.

Reviewing and Addressing Risks

Regular reviews help maintain effective workflows and identify areas for improvement. If objectives are not met, it’s critical to:

Regular reviews help maintain effective workflows and identify areas for improvement. If objectives are not met, it’s critical to:

- Identify the risks and challenges that led to the shortfall: Understanding the root causes of why objectives were not achieved is crucial. This involves a thorough analysis of internal and external factors that may have contributed to the issue. It could be a lack of resources, employee turnover, changes in market conditions, or unforeseen events. Identifying these risks and challenges is the first step towards addressing them and preventing future occurrences.

- Develop and implement appropriate risk mitigation strategies: Once the risks are identified, the next step is to create risk mitigation plans. These strategies should be aimed at reducing the likelihood of the risk occurring or minimizing its impact if it does occur. This could involve revising processes, providing additional training to staff, investing in new technology, or enhancing communication channels.

Delving deeper into the process of risk management, it’s imperative that the organization fosters a proactive risk-aware culture. This means encouraging open communication about risks at all levels of the organization and ensuring that there is a clear understanding of who is responsible for managing specific risks. A proactive approach to risk management not only helps in addressing the current issues but also aids in anticipating potential future challenges, allowing the organization to prepare or avoid them altogether.

In addition, implementing a systematic approach to risk management, such as the one outlined in ISO 31000, can provide a structured framework for identifying, analyzing, evaluating, and treating risks. This framework helps ensure that risk management practices are integrated into all organizational processes and that risk-informed decision-making is happening at the organizational level.

Furthermore, it’s important to monitor the effectiveness of the risk mitigation strategies put in place. This involves setting up key risk indicators (KRIs) that can signal the need for action before risks escalate into more significant problems. Regular monitoring and reporting on these indicators enable organizations to respond quickly to changes and maintain control over their risk landscape.

Rand addressing risks is not a one-time task but an ongoing process that plays a critical role in achieving quality objectives and ensuring the organization’s resilience. By continuously identifying risks, developing tailored mitigation strategies, and fostering a risk-aware culture, organizations can navigate the complexities of their operating environments more effectively and sustain their progress towards quality excellence.

ISO 9001 Quality Objectives – Conclusion

ISO 9001 Quality Objectives are a strategic tool that, when used effectively, can drive an organization towards continual improvement and heightened customer satisfaction. By setting SMART objectives, meticulously planning their implementation, and continuously monitoring and revising them, organizations can enhance their Quality Management System (QMS) and achieve superior performance.

Elaborating further, the use of SMART objectives—those which are Specific, Measurable, Achievable, Relevant, and Time-bound—provides a clear and structured approach to setting goals. These objectives are not just arbitrary targets; they are carefully crafted to align with the company’s strategic vision and the needs of its customers. When objectives are SMART, they are more likely to be understood and embraced by the entire organization, which is vital for successful implementation.

Meticulous planning is another cornerstone of effective quality objectives. This involves outlining the resources required, assigning responsibilities, and determining the methods for achieving each objective. Planning also includes anticipating potential obstacles and incorporating appropriate risk management strategies. This level of detail ensures that the path to achieving quality objectives is as smooth as possible and that everyone involved is prepared for the journey.

Continuous monitoring and revision of quality objectives are what make the ISO 9001 framework so powerful. In a dynamic business environment, change is the only constant, and a QMS must be agile enough to adapt. By regularly reviewing objectives in the context of performance data, customer feedback, and other relevant information, organizations can make informed decisions about where adjustments are needed. This might involve setting new targets, revising existing ones, or even overhauling strategies that are no longer effective.

The ultimate aim of ISO 9001 Quality Objectives is to instill a culture of excellence that permeates every level of an organization. This culture is characterized by a collective commitment to quality, where continuous improvement is not just a goal but a mindset. As organizations embed this mindset into their operations, they not only meet but often exceed customer expectations, leading to greater customer loyalty, market share, and competitive advantage.

ISO 9001 Quality Objectives are much more than a set of requirements; they are a blueprint for building a robust, customer-focused organization. When leveraged to their full potential, these objectives can transform the way a company operates, delivering benefits that reach far beyond compliance and into the realm of excellence in quality management.

🕒 Book Your Free 45-Minute Consultation

Have questions about ISO/IEC 17025 or ISO 9001 implementation or accreditation? Schedule a free 45-minute consultation with me to discuss your Company or laboratory’s needs and how we can achieve compliance together.

Schedule Your Consultation